When choosing an injection molder to produce your plastic parts, it’s essential to consider more than just cost. Selecting a partner to help you achieve your sustainability goals for your function or product is also necessary.

One way to achieve this is by choosing recycled or biodegradable plastic. Another way is to work with a manufacturer with experience using all kinds of materials in injection molding.

Recycled Plastics

Choosing sustainable plastic injection mold makers helps companies save money, protect the environment, and boost their image. They can also help you avoid paying expensive fees for waste disposal.

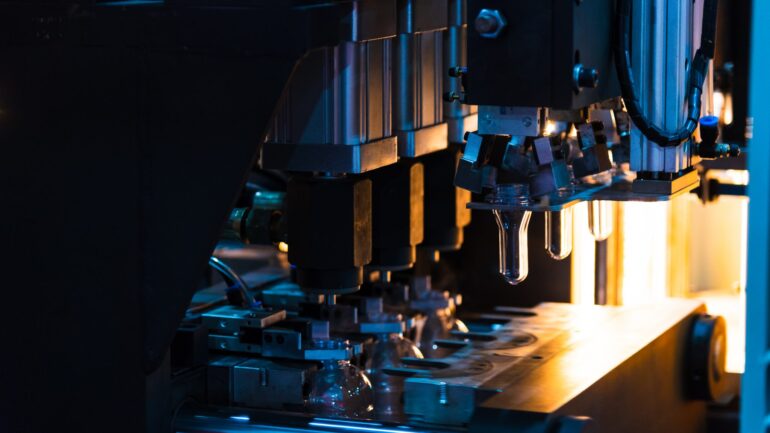

The plastic injection molding process involves melting plastic into pellets, then injecting it into a mold to make a final product. This process is incredibly efficient and can produce high-quality parts that customers are satisfied with.

However, this process can result in scrap and other problems if recycled plastic is not ground into uniform pellets or if it is contaminated with dirt, dust, and other materials that affect the quality of the final product.

Fortunately, technology has helped eliminate much of this waste through advanced melt filtration systems that are fully automated and can remove particles as small as 70 microns in diameter. By utilizing this method, many manufacturers have reduced their waste production and optimized the efficiency of their plastic molding operations.

Biodegradable Plastics

When choosing a plastic injection mold maker, you want to ensure they can produce biodegradable products. This will reduce their carbon footprint and allow them to be environmentally friendly.

Biodegradable plastics are manufactured with various organic materials and chemical additives that degrade into carbon dioxide, water, biomass, or mineral salts. The materials should not cause harm to the environment and should not pose a risk to human health.

However, it is essential to note that not all biodegradable plastics are created equal. Some may fragment rather than biodegrade in the environment, which can negatively impact our soils and oceans.

Plastics must be made from renewable plant and organic resources to be completely biodegradable. These include corn, potatoes, soy, wheat, and sugarcane.

Starch-Based Thermoplastics (TPS)

When choosing a plastic injection mold maker, choosing one committed to sustainable production methods is essential. This can help reduce your carbon footprint by reducing pollution, limiting the use of fossil fuels, and ensuring that your products are biodegradable.

Starch is the second most common renewable source after cellulose, and it can be used to produce biodegradable materials such as thermoplastic starch (TPS). It is inexpensive, easy to obtain, and often mixed with other materials for plastic injection molding.

It is also 100% biodegradable and can be carbon neutral when disposed of. This makes it a great selling point for companies that want to be eco-friendly and are concerned with their environmental impact.

Sustainable Packaging

Injection molding is a process that requires a lot of energy to run. In addition, it produces a significant amount of scrap in landfills.

With that in mind, injection molders must choose a supply chain partner that shares their sustainability goals. Look for a supplier certified as a green business with sustainable practices.

Another way that injection molders can support sustainability is by choosing packaging materials that are renewable or biodegradable. This can help reduce carbon emissions and save money on transportation costs.

With that in mind, plastic injection molders must choose a supply chain provider that shares their sustainability goals. Look for contract stipulations requiring recyclable plastics or other environmentally friendly packaging.